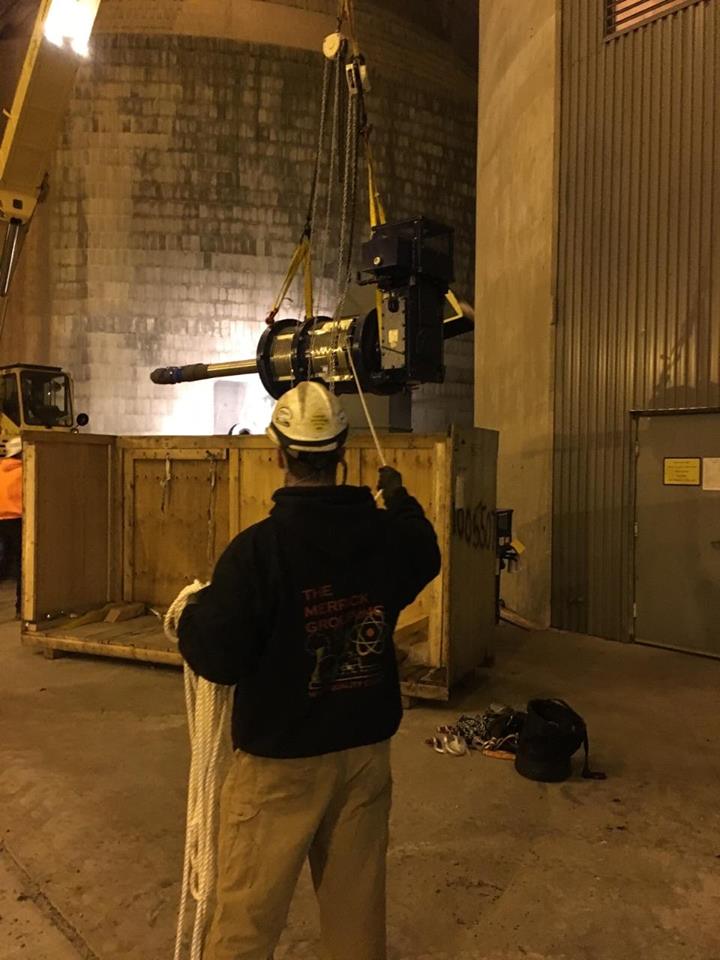

The Merrick Group’s decades of experience serving the power plant industry has grown its list of comprehensive services in both power plant cleaning and maintenance. Strictly adhering to evolving industry standards, The Merrick Group makes it their goal to ensure maximized quality and safety on every job. Their team of technicians are highly trained to ensure power plants are performing optimally and are safe for employees and the general public.

Fossil Fuel and Thermal Power Plant Maintenance

Lifetime of a Fossil Power Plant

The lifetime of a fossil power plant depends on which type of power

it offers, government regulations, and how well it is maintained.

A typical operational lifetime ranges anywhere from 30 to 50 years. A recent study in the journal Science estimates that a large majority of coal, natural gas, and oil power plants will have reached their life expectancies by 2035. These estimates are mostly based on our knowledge of how long technology typically lasts (Grubert). However, a power plant may be allowed to operate past its technical lifetime if it can prove it is in good condition and it’s up to current regulations. The most effective way to extend the lifetime of a power plant is to adhere to a comprehensive power plant cleaning and maintenance schedule.

Fossil Power Plant Cleaning Services

Cleaning services can help prolong the life cycle of fossil power plants by preventing costly accidents.

The Merrick Group offers a variety of cleaning services aimed to keep power plants up and running as safely as possible:

- Condenser cleaning and tube plugging: Aims to maximize heat transfer capacity by removing contaminants and pollutants like dirt, algae, and scum that are commonly found in open water (ie: seawater or river water).

- Heat exchanger cleaning: Aims to maximize your bottom line by identifying possible fouling of exchangers which can affect performance and output and overall efficient heat transfer.

- Underground piping: Aims to improve production by preventing buildup and blockages of debris that can cause issues over time. Solutions may include hydro milling and retro jetting.

Fossil Power Plant Maintenance Services

Regular maintenance can go a long way in maximizing day-to-day efficiencies that can impact a power plant’s ability to keep up and running. The Merrick Group offers maintenance solutions for all facets of the power plant industry including outages and on-line maintenance like:

- Cooling tower maintenance: Ensures cooling towers are functioning at peak performance levels while mitigating the risk of issues caused by improper or irregular maintenance. This involves tailoring solutions to each facility’s unique needs while focusing on efficiency improvement, downtime reduction, and decreased expenses for profitable operation at each location. Solutions may include (but are not limited to): structural repairs, nozzle inspection, and replacement, handrail and ladder inspection, mechanical fan service, concrete and steel coating prep and repair.

- Inspections: Determines whether acceptable conditions exist for a plan to operate up to AMPP’s current standards. Inspections are undertaken by specialists with either a AMPP Coating Inspector Level 1 certification and/or a AMPP Coating Inspection Level 2 certification.

- Coating applications: Aims to minimize the effects of corrosion on operations by utilizing specially trained employees to apply coating which will protect substrates from the damaging effects of rain, sunlight, wind, heat, cold, humidity, and oxygen in various combinations and cycles.

Industrial Service Testimonials

I just wanted to commend [The Merrick Group] employees that I worked with for the last 4 months performing a hydro-vac excavation to support an upcoming underground pipe replacement. Your crew performed their job daily in a safe, professional manner. The crew also demonstrated high standards with attention to detail of the work order, following the prints, and a daily log of the work performed.

– Tony Zielinski, Supervisor, Major Projects – Susquehanna Steam Electric Station

Thank you for sending Mike and Justin and their teams who provided tube cleaning services for us during Vogtle 1R24. We have been very pleased with the leadership provided by [The Merrick Group] as well as the excellent work ethics the crew members displayed. They are a great group of guys, and we are looking forward to having them return in the future. Dennis and I had one goal in mind when The Merrick Group arr- ived. That goal was to support your team in any way needed to help them be successful. As it turns out, your guys know how to get things done and needed very little support. Once they got their hands on contact names and numbers, they made stuff happen. They made our jobs very easy and we really appreciate that. Thanks for sending the “A” Team!

– Jeff Faegin, Task Manager – Vogtle Nuclear Plant

Merrick’s Eddy Current Testing always surpasses my expectations for online work. The schedule can change at the drop of a hat, and the crew is more than willing to adapt and complete the work to support the system outage window. They performed work in SSES’s B Diesel SOW in a timely manner but most importantly, they did it safely. Prior to starting work, walkdowns and crew briefs were prioritized to ensure work on safety-related equipment was performed with quality.

– Megan Yackoski, Senior Engineer – Susquehanna Steam Electric Station