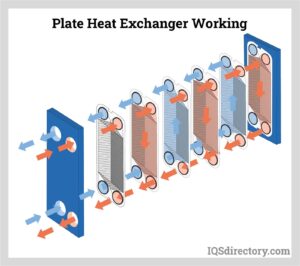

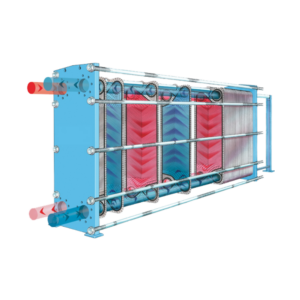

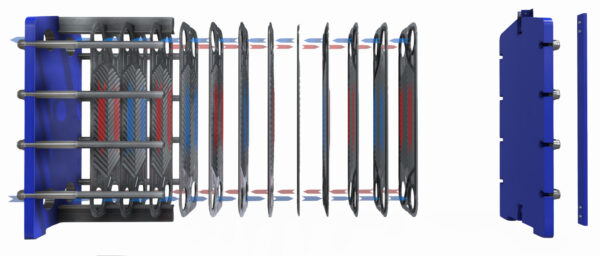

Plate and Frame Heat Exchangers are stacked stainless steel plates connected and sealed with gaskets or welds to transfer heat between two fluids. Cleaning heat exchanger systems is critical and should be part of your routine maintenance and service programs. Due to the small size of the passages in the plates, solid debris can hinder the flow of the liquids, hence decreasing efficiency.

There are a number of methods in plate and frame heat exchanger cleaning. The Merrick Group’s team of highly trained technicians will provide a thorough cleaning and inspection of your heat exchanger. With decades of experience, our heat exchanger technicians will recommend the best course of action for your maintenance and cleaning needs.

Schedule Heat Exchanger Cleaning

How To Clean and Maintain the Plate and Frame Heat Exchanger?

There are a number of industrial cleaning servicing methods that can be applied to the heat exchanger system. The heat exchanger is designed to have a moveable end frame that is held in place by compression bolts. Removing these compression bolts and the end frame gives technicians full access to the plates. The individual plates are connected by gaskets. At this stage of the process, the plates are cleaned and inspected.

Heat exchanger technicians may opt to replace or clean and reinstall the original gaskets. The unit is then reassembled and inspected. If you notice the pressure is increasing and your temperature is decreasing in your plate and frame heat exchanger, you should not wait too long before scheduling a heat exchanger inspection. The problem is prone to get worse and more costly to fix or replace.

Rely on the expertise of The Merrick Group team for the maintenance of your heat exchanger unit. Our skilled technicians have extensive training to meticulously dismantle the unit, conduct a comprehensive inspection, and perform a thorough industrial cleaning and servicing of your plate and frame heat exchanger. You can trust us to handle the task with utmost care and attention to detail.

Learn about The Merrick Group Advantage

Plate and Frame Heat Exchanger Cleaning Methods

Plate and Frame Heat Exchanger Cleaning Methods

The two predominant methods of plate and frame heat exchanger cleaning are mechanical and chemical. In addition, technological advancements and improved equipment have introduced some optional modes such as clean-in-place, backflushing, and disassembled cleaning.

Mechanical Cleaning of Plate and Frame Heat ExchangerUsing mechanical methods to clean plate and frame heat exchangers is the physical removal of debris or deposits. Mechanical cleaning also enables technicians to use greater precision with specialized tools. Our experts at The Merrick Group deploy some of the latest technologies through water lancing and high-pressure hydro blasting. |

Chemical Cleaning of Plate and Frame Heat ExchangerChemical cleaning circulates cleaning solutions through the plate and frame heat exchanger system to dissolve and remove the debris or residual deposits. Chemical cleaning is often faster than other methods and normally does not require the unit to be disassembled. |

As one of the best industrial chemical cleaning companies for heat exchangers, our highly trained technicians at The Merrick Group are capable of professionally performing all cleaning methods. Our heat exchanger service company offers global assistance so call to discuss your needs:

Clean-in-Place (CIP) of Plate and Frame Heat Exchanger

The clean in place (CIP) heat exchanger method is an effective means of servicing units that need more frequent cleaning. CIP for plate and frame cleaning is efficient as it requires no disassembly of the heat exchanger system and minimizes the need for operational stoppages. The CIP method will have the best results if they are conducted routinely as part of the service regime and before the system has completely shut down.

Plate and Frame Heat Exchanger Backflushing

If your heat exchanger is prone to clogging from various debris in your system, backflushing may be the most effective method for you. A heat exchanger backflushing service is reversing the flow through your plate and frame to dislodge and remove the solids or sediment that decrease the unit’s efficiency. By sending these contaminants back through the system the same way they entered, backflushing is an easy and cost-effective means to clean your heat exchanger.

Disassembled Cleaning of Plate and Frame Heat Exchanger

If you are unsure which cleaning method is best for your heat exchanger system, The Merrick Group can assist. Contact us and we will discuss your options.

Email The Merrick Group With Your Heat Exchanger Service Request

What Chemicals Are Used While Chemical Cleaning?

Most chemical cleaning services that are circulated through heat exchangers are composed of strong acids or alkalis. Some of these chemical agents are potassium hydroxide, hydrochloric acid, nitric acid, sulfamic acid, phosphoric acid, and sodium phosphates.

It is important to use the right industrial descalers when performing a chemical cleaning to avoid damaging the system or sensitive underlying metals. The Merrick Group is very proud of our partnership with industry-leading manufacturer of specialized industrial maintenance products, Goodway Technologies. Goodway is globally renowned for its advanced cleaning and maintenance products.

The Merrick Group relies on the industry experts of Goodway Technologies to recommend the best industrial cleaning products, sometimes even being on-site and training our technicians on their use. Together, this partnership ensures your heat exchanger is being expertly serviced by professionals.

Learn more about Chemical Cleaning

Importance of Plate and Frame Heat Exchanger Cleaning

Contact The Merrick Group For Plate and Frame Heat Exchanger Cleaning

Contact The Merrick Group for plate and frame heat exchanger cleaning needs. We are proudly exercising our services in nuclear power plants, petroleum refineries, and a wide variety of other industries. Our professional technicians will travel to your industrial equipment as a one-time service or we can schedule regular or routine maintenance. Inquire about our industrial cleanings, maintenance and inspections today.